One of the great challenges facing the meat industry is the stability of quality throughout the product's shelf life. But after all, do you know what this term means?

What is Shelf Life and why is it important?

The most serious food safety issues that result in immediate health problems for consumers and recalls of potentially contaminated products are associated with microbiology, and especially pathogenic bacteria.

Derived from the English vocabulary, the word shelf life is directly related to the life span or shelf life of food, also popularly known as "expiration date". ANVISA defines shelf life as the time interval during which food remains safe and suitable for consumption, taking into account the conditions established by the manufacturer. It is therefore necessary that the food:

- Maintain its characteristics, with no significant loss of any of its nutrients or components;

- It remains safe for consumption, without causing food poisoning or infections caused by pathogenic micro-organisms or similar during storage;

- Maintain their respective sensorial qualities and do not deteriorate, making consumption inappropriate.

For food sold in Brazil, attention must be paid to complying with the main requirements and regulations established by law that determine the general rules for marking the expiry date on product labeling, in order to avoid information that could mislead consumers as to the true shelf life of the food to be consumed.

The Consumer Defense Code (CDC), on the other hand, stipulates that the presentation and offer of products must be carried out in such a way as to ensure correct, precise, clear information in Portuguese regarding expiry dates.

Factors influencing shelf life

Shelf life is taken into account from the moment the food is manufactured and must be informed to consumers on the labels of packaged foods. There are many factors that influence the shelf life of products, which are classified as intrinsic and extrinsic.

Intrinsic factors

Intrinsic factors are those related to the food itself, including humidity, pH, water activity (aw), available oxygen, microorganism count, among many others. Variables such as raw material, quality, formulation and product structure also influence intrinsic factors.

Extrinsic Factors

Factors external to the product are called extrinsic. Storage conditions, packaging and distribution are good examples of these.

The interaction between both factors contributes to the stimulation or inhibition of a series of processes that limit the shelf life of products, which can be classified as physical, chemical, microbiological, among others. It is also important to know the production processes and the respective factors that have an impact on shelf life.

Learn more about Shelfmax and Shelfmax (aw)

We know that shelf life is an extremely important factor during the manufacture of food and that's why we developed Shelfmax and Shelfmax (aw): our exclusive lines, dedicated and designed to increase the shelf life of meat products, whether they are processed or chilled cuts.

Shelfmax

Thinking of an integrated solution to preserve the shelf life of chilled poultry, beef and pork cuts, we developed the Shelfmaxa combination of additives and natural compounds with preservative, antioxidant and antimicrobial properties.

To prove its efficiency in preserving food, we carry out laboratory analyses and tests, examining the amount of micro-organisms found in each sample.

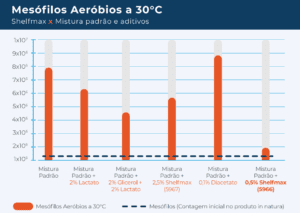

The graph below shows the count of aerobic mesophilic microorganisms at 30ºC in tests carried out in a controlled environment on chilled chicken cuts seasoned after 77 days of production. To carry out the tests, we used a standard mixture (salt, spices, erythorbate and phosphate) and compared it with tests of the same mixture with the addition of additives (diacetateglycerol and lactate) and the Shelfmax (5966 e 5967).

We can see that the Shelfmax (5966) was much more effective in preventing the multiplication and development of aerobic mesophilic microorganisms when compared to the standard mixture and additives, maintaining the quality and greater preservation of the food.

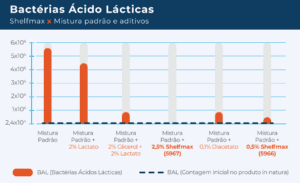

The lactic acid bacteriaas well as others, are responsible for spoilage in meat products. Other tests carried out on chilled, seasoned chicken cuts demonstrate the superior efficacy of Shelfmax (5966 and 5967) when compared to the use of the standard mixture (salt, spices, erythorbate and phosphate) and additives (diacetate, glycerol and lactate).

The application of Shelfmax in meat products in both tests was able to significantly inhibit the development of microorganisms responsible for food deterioration, ensuring greater stability and preservation, extending the shelf life of the products observed.

Shelfmax (aw)

Ready-to-eat meat products need special care because many are consumed without cooking, making them good substrates for pathogenic microorganisms.

Our Shelfmax (aw) integrated solution is a blend of additives and ingredients that combines two preservation factors to control microbiological growth: reduced water activity combined with the use of natural extracts with antimicrobial properties.

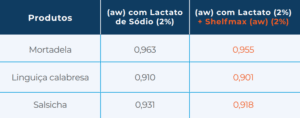

Its efficiency could be proven through analyses in which we produced samples of various meat products using sodium lactate, and compared the water activity found with other samples made using sodium lactate, adding the Shelfmax (aw).

The conclusion of the tests showed that its application was able to reduce the water activity found in processed meat products such as mortadella, sausage and Calabrian sausage, while maintaining the microbiological safety required to market them.

New Max

Since 1992, we have been specialists in guaranteeing personalized and innovative solutions for the food industry, making a difference to the most diverse projects. A benchmark in the production of additives, flavors, natural colorings, integrated solutions, spices and condiments, we are constantly engaged in research and development to produce products with the highest levels of quality and reliability.

Are you interested and would like to know more about Shelfmax and Shelfmax (aw)? Contact us and speak directly to one of our specialized technical consultants to develop your project.